A solid two-component modified polyurethane structural adhesive, solvent-free, isocyanate-free, almost zero VOC, anti-pollution after curing, green environmental protection, excellent anti-aging ability and other advantages. Fast deep curing, suitable for rapid bonding and sealing in automobiles, rail transit, electronic appliances and other fields. This product complies with environmental protection requirements, does not contain harmful substances in GB18583 "Limitations of Hazardous Substances in Adhesives for Interior Decoration Materials", and complies with EU ROHS and REACH environmental protection standards. In line with the German automotive industry environmental standards.

Product Features

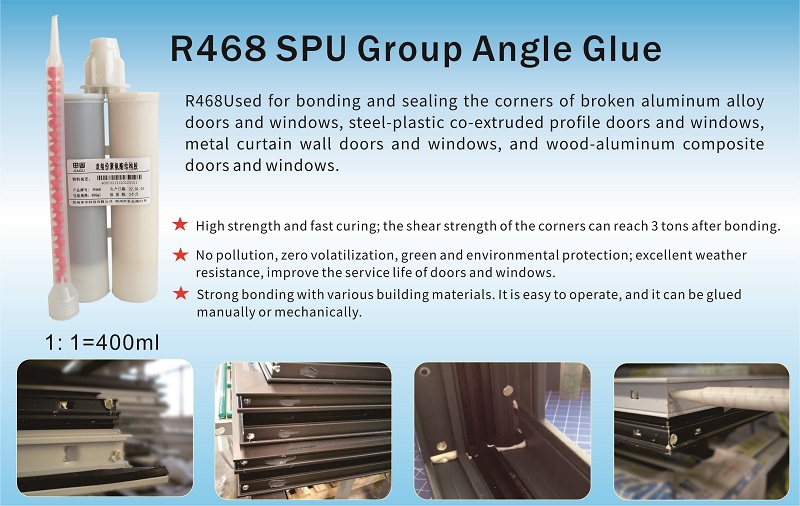

1. No pollution, zero volatilization, green and environmental protection; excellent weather resistance, improve the service life of doors and windows.

2. Very high bonding strength, fast curing; the shear strength of the corners after bonding can reach 3 tons.

3. Firmly bond with various building materials.

4. Easy to operate, both manual and mechanical gluing can be done.

Application

1. The structural bonding and sealing of the corners of the broken bridge thermal insulation aluminum alloy doors and windows.

2. Structural bonding and sealing of the corners of steel-plastic co-extruded profile doors and windows, wood-aluminum composite doors and windows.

3. Structural bonding and sealing of metal curtain wall doors and windows.

4. Structural bonding and sealing of ordinary aluminum alloy doors and windows, wooden aluminum doors and windows.

Instructions:

1. Unscrew the nut on the top of the hose, remove the buckle cap, and install the mixing nozzle.

2. Install the pneumatic glue gun, adjust the pressure of the glue gun, and extrude the glue. Discharge the fully mixed colloid (about 20g).

3. Put the mixed glue in a dry, dust-free and grease-free cavity (the amount of glue to be squeezed is 20g).

4. Insert the corner code and pull it out several times to ensure that the glue is evenly applied to the corner code.

5. Install the other end profile and pull it out several times. The upper corner machine hits the corner.

6. Pour the two-component angle glue into the prefabricated hole until the glue overflows at the card position.

7. Use a non-dyeing cotton cloth to moisten the cleaning agent, and clean the corner overflow glue in the same direction.

Matters Needing Attention

1. After the initial solidification of this product, the strength gradually increases, and the residual glue on the surface of the profile should be removed in time.

2. When performing coloring, on-site testing is required to ensure compatibility with the colloid.

3. When used in water immersion, it should be fully cured before immersion (dry for 7 days at 23°C).

Packing Specification

Double tube hard pack: 400ml/pcs, 24pcs/carton.

Storage Method

To store in a cool, ventilated, dry place below 27°C. The storage period is 6 months.